Description

Beacon Medaes Horizontal Medical Single Zone Valve Box NFPA

- Valves are cleaned for medical service per CGA guidelines.

- Order gauges (sold separately) for zone valve application.

- When installing sensors inside of zone valve box, order one remote sensor kit per gas

- Meets or exceeds NFPA code for Medical Gas Pipeline System Components.

- Made in the USA

Zone Valve Box Assembly

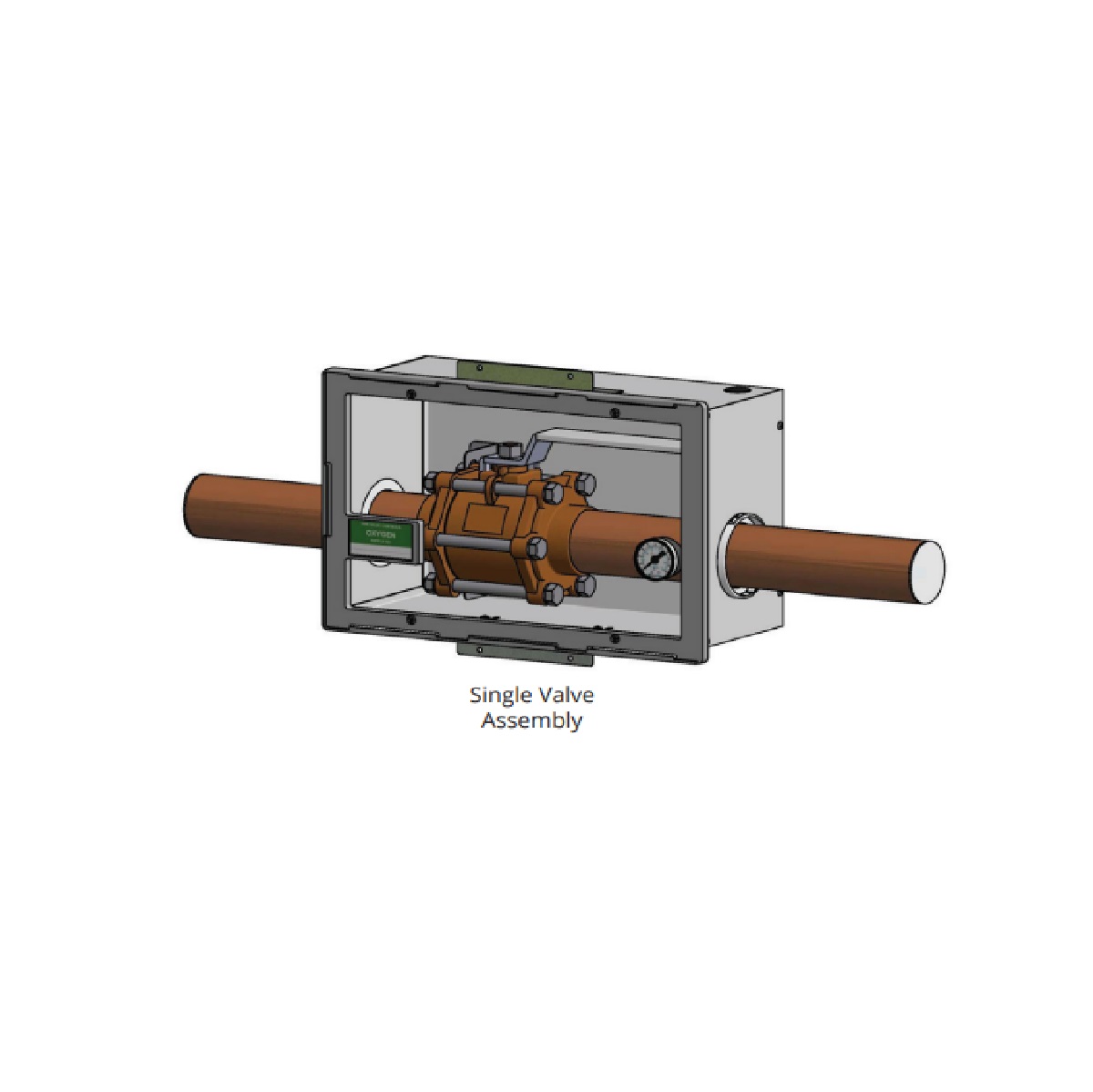

Valves shall be full port, double seal, ball-type with three

piece bronze/brass body and a chrome plated brass ball.

Valves shall be designed for a maximum working pressure

of 600 psig WOG or vacuum service to 29″ Hg. Valve body

shall have reinforced PTFE ball seat and reinforced PTFE

stem seals, and stem shall be blowout proof. All valve

materials shall be compatible with USP oxygen, nitrous

oxide, medical air, carbon dioxide, helium, nitrogen, argon

and mixtures thereof.

A 1/4 turn of the handle shall be required to operate the

valve from OPEN to CLOSED position. The valve shall be

securely attached to the box and provided with type K

copper tube extensions for making connection to system

piping outside the box. All valves shall be serviceable in the

line, supplied clean and prepared for oxygen service.

All valve assemblies have a total of three 1/8″ NPT ports with

pipe plugs. One port is used as a provision for connection

of a gauge and shall be located on the terminal outlet side

of the valve to register pipeline pressure or vacuum. The

second port is used as a provision for a DISS connection of

a gas sensor. The third port is used for purging during the

brazing process and is located upstream of the valve.

The zone valve and box assembly shall meet all requirements

of NFPA 99, CAN/CSA Z7396.1-09 and AS2896-2011.

The valves conform to MSS SP-110. Type K copper tube

extensions conform to ASTM B88, UNS No. C12200, and

H58 temper. The gauges shall conform to ANSI B40.1.

Zone Box Design

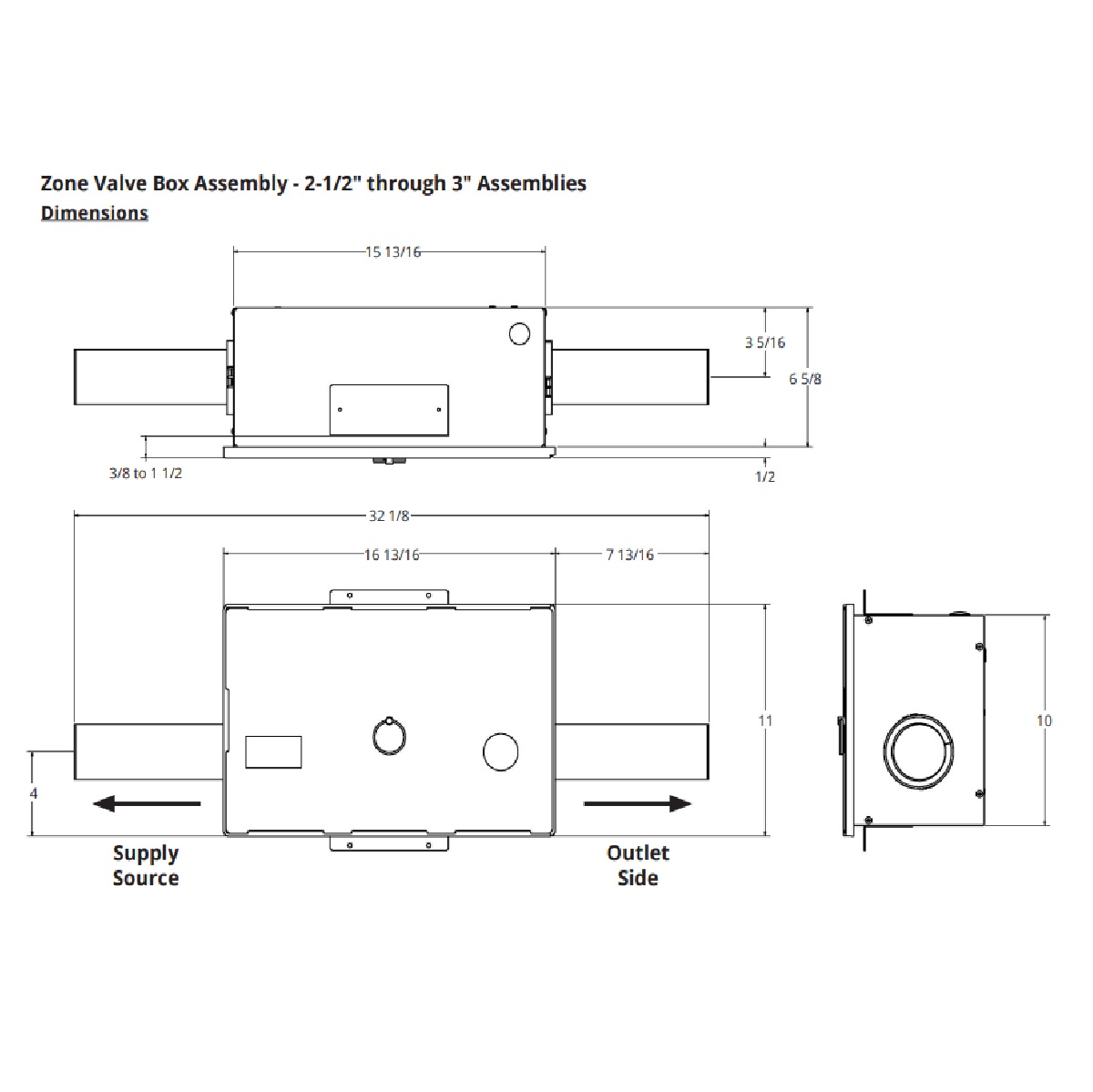

The zone valve box shall be constructed of 18-gauge steel

with white epoxy finish. The 1/2” through 2” valves require

a rough wall opening of 13 5/8″ wide x 4″ deep. The 2-1/2”

and 3” valves require a rough wall opening of 15-7/8” wide

x 10” high x 6-11/16” deep. For ease of installation, two

18-gauge galvanized steel mounting brackets, adjustable

from 3/8″ thick to 1.5″ drywall, are provided.

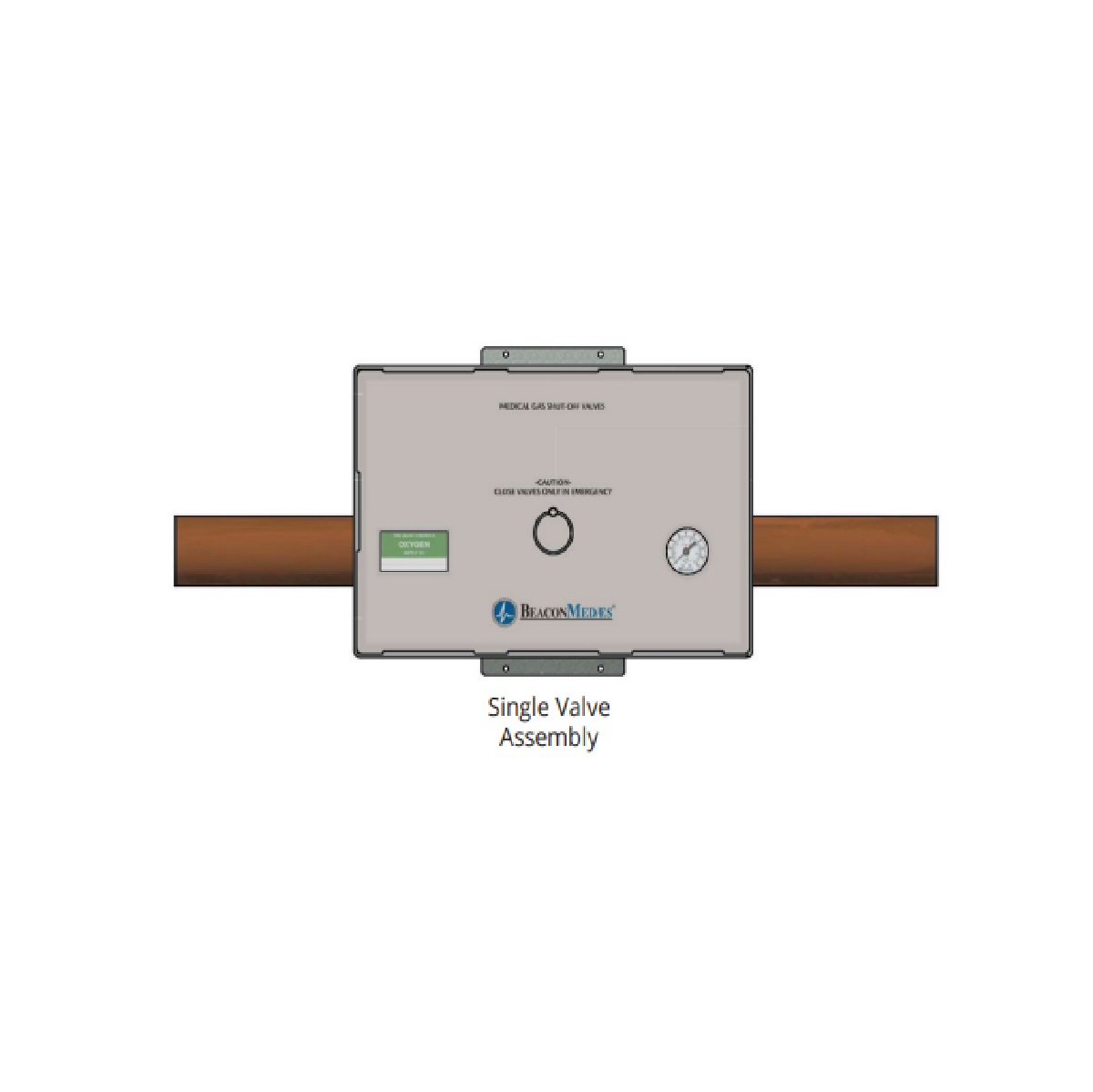

The zone valve box assembly shall have a sliding, opaque

door with pull ring and clear gauge window. The door shall

be capable of sliding to the right to facilitate installation

requirements. In an emergency, the door shall SNAP OUT

by pulling the pull ring forward without exposing sharp

edges.

The zone valve box shall be provided with an advanced

polymer (ABS) trim frame designed for high impact

resistance and capable of adjusting to variations in wall

thickness up to 1″ below flush. The design allows for the

configuration of up to 7 valves within the rough-in box

assembly. Gas flow should be from left to right. Nylon 6/6

Insulated grommets allow for ease of valve replacement

and reorientation within the rough-in box. The Zone Valve

Box door is treated with Biomaster (see table on pg.4 for

details). The zone valve box assembly shall be supplied with

color-coded gas identification labels. The gas identification

labels are also available online for printing. The assembly

door shall have a label that reads:

-CAUTION- CLOSE VALVES ONLY IN EMERGENCY