Description

Specifications

Control Panel

- UL listed control panel in a NEMA 12 enclosure with a 5.7″ Touch Screen Display

- Manual reset for all alarms

- All control and alarm functions shall remain energized while any pump in the system remains electrically online

- Ethernet connectivity with embedded webpage for remote monitoring, password protected for remote adjustment of all operating parameters

- Lag pump will start automatically should the lead pump fail to operate

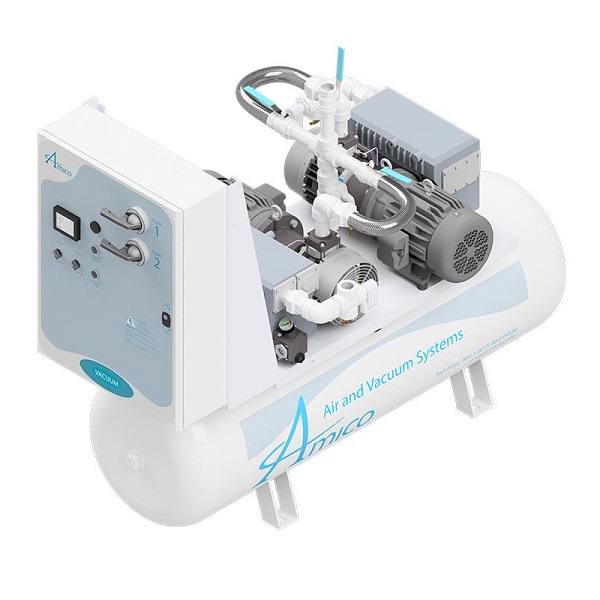

Vacuum Pump

- Vacuum pump shall be an Oil-Sealed Rotary Vane type with air cooled design

- Dynamically balanced multi-vane design

- Bearings are permanently lubricated and sealed

- Pump shall be direct driven

- Equipped with a built-in anti-suck back valve mounted at the pump inlet

- Means of removal of the vacuum pump for service or replacement without interruption to the system

Air Receiver

- ASME certified with provisions for isolating the receiver without interruption of the vacuum service

- Rated for full vacuum service with a minimum 200 psig design pressure

- Inside of the receiver consists of a two-part epoxy coating providing rust protection equal or better than that achieved by galvanizing

Features

General Features

- Oil-Sealed Rotary Vane vacuum pump with air cooled design

- UL listed control panel in a NEMA 12 enclosure with a 5.7″ Touch Screen Display

- Ethernet connectivity with embedded web-page for remote monitoring, password protected for remote adjustment of all operating parameters

- Inside of the receiver consists of a two-part epoxy coating providing rust protection equal or better than that achieved by galvanizing

Design Options

- Please click the pink “manuals” icon above to download our NFPA design guide for air compressors.

- Please click the purple “ordering guide” icon above to download our sizing guide for Source equipment.

Reviews

There are no reviews yet.